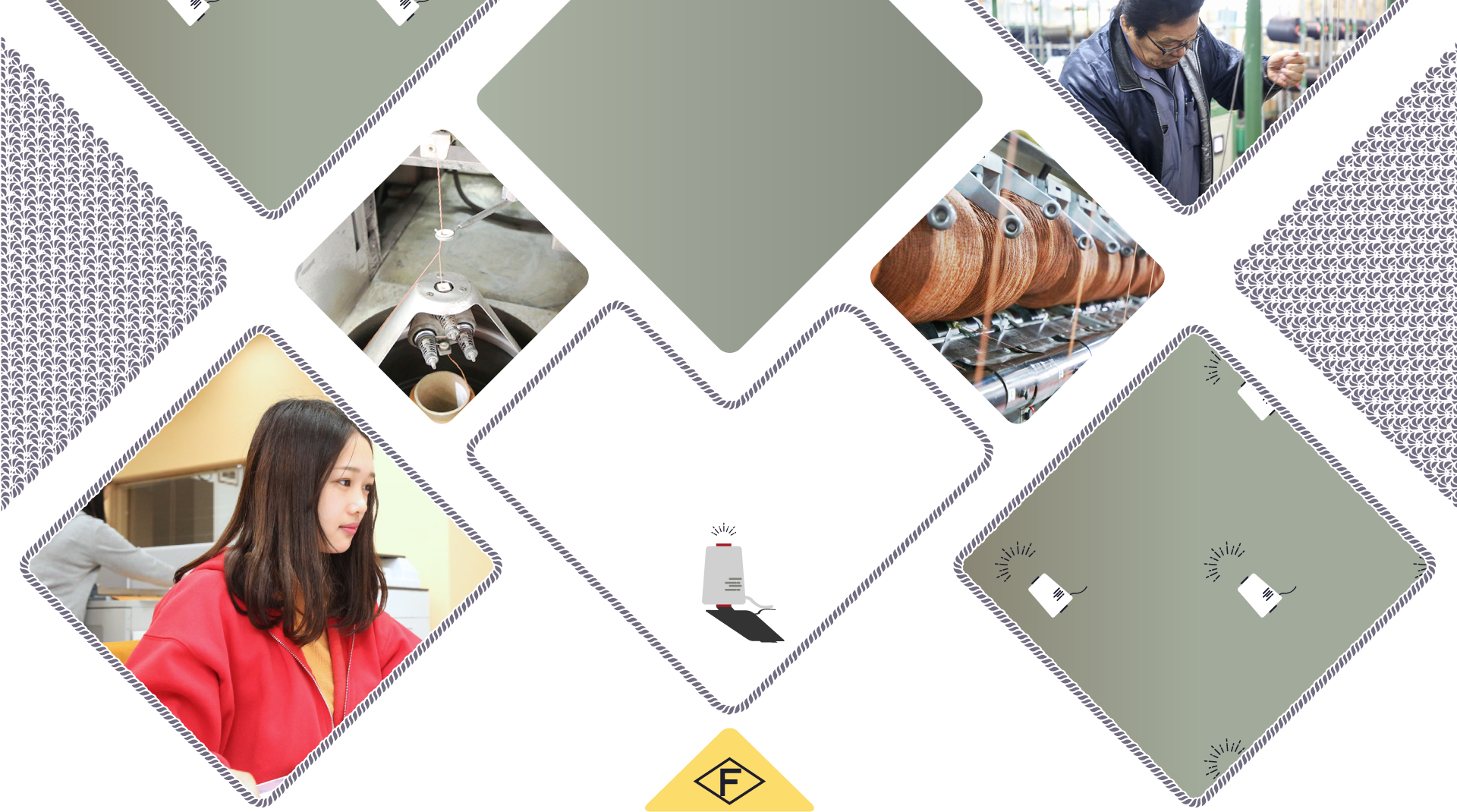

| Intermingling / Twist-mingling |

Cable twisting | Heatsetting | |

| Ring twisting | Rewinding | Twisting of glass fibers | Spinning and processing of PP-BCF |

| single yarn | 300~4000dtx | ||||

| tacs | 30~50/m, As for twist-mingling 50~100 turn/m(S-turn+tacs+Z-turn) | ||||

| total yarn processed | 1000~8000dtx | ||||

| material | BCF nylon 6 or 6,6 , PET, PP, or other synthetic filaments | ||||

| final usage | carpets, car mats, interiors, industrial materials | ||||

| facility | 43 machines with 226 spindles (of which 4m/c, 16 spindles also for twist-mingling) | ||||

| production capacity | intermingling: 600tons/month, twist-mingling: 50tons/month | ||||

| delivery time |

|

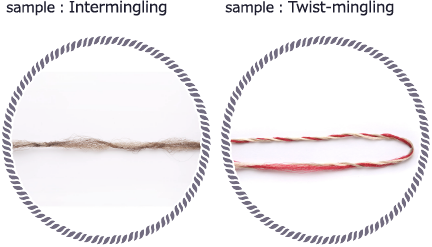

| singles | 700~4,000dtx |

| twisting level | 40~280 T/m (Final S or Z) |

| total yarn processed | 1,400~12,000dtx |

| material | BCF nylon 6 or 6,6 , PET, PP, or other synthetic filaments |

| final usage | carpets, car mats, interiors, industrial materials |

| facility | 32 spindles=1 m/c, 48 spindles=6 m/c, 88 spindles=2 m/c, 96 spindles=2 m/c |

| production capacity | 150 tons/month |

| delivery time | standard delivery within 4 weeks for a lot of 5 tons |

| heatsetting |

Superba 36 spindles Straight/Frieze 100 tons/month |

| twisting level | 70~270T/m(S or Z) |

| yarn processed | 1000~8000dtx |

| material | BCF nylon, PP |

| final usage | carpets |

| facility |

Superba 36 spindles |

| production capacity | Straight/Frieze 100 tons/month |

| delivery time | standard delivery within 4 weeks for a lot of 5 tons |

| singles | 300~4,000dtx | ||||

| twisting level | 30~200 T/m (Final S or Z) | ||||

| total yarn processed | 1,000~8,000 dtx | ||||

| material | BCF nylon 6 or 6,6 , PET, PP, or other synthetic filaments | ||||

| final usage | carpets, car mats, interiors, industrial materials | ||||

| facility | 8 3/4-inch ring twister with 60 spindles= 2 m/c | ||||

| production capacity | 50 tons/month | ||||

| delivery time |

|

| total yarn processed | 600~5,000dtx |

| package size | 50g~4kg |

| bobbins | 10-inch cone type, unless specified. 12-inch parallel bobbin is possible. |

| material | BCF nylon 6 or 6,6 , PET, PP, or other synthetic filaments |

| final usage | carpets, car mats, interiors, industrial materials |

| facility | 20 spindles= 9 m/c, 8 spindles= 2 m/c, 4 spindles= 2 m/c, 204 spindles in total |

| production capacity | 150 tons/month |

| delivery time | standard delivery within 2 weeks for a lot of 5 tons |

| singles | #37(1360dtx)~#225(220dtx) |

| twisting level | 1.7T/inch~8.0T/inch |

| type of plys | a number of combination, such as 1/2~7, 4/2, 1/6/3, 1/12/3 |

| total yarn processed | 440~9520dtx |

| material | E-type glass fiber, C-type glass fiber |

| final usage | wire harness, insulator for batteries, chopped yarns, industrial materials |

| facility | 4-1/2" rings=500, 5-1/2" rings=700, and 6-1/2" rings=472 spindles |

| production capacity |

down-twisting: 50 tons/month up-twisting: 50 tons/month |

| delivery time | standard delivery within 4 weeks for a lot of 3 tons |

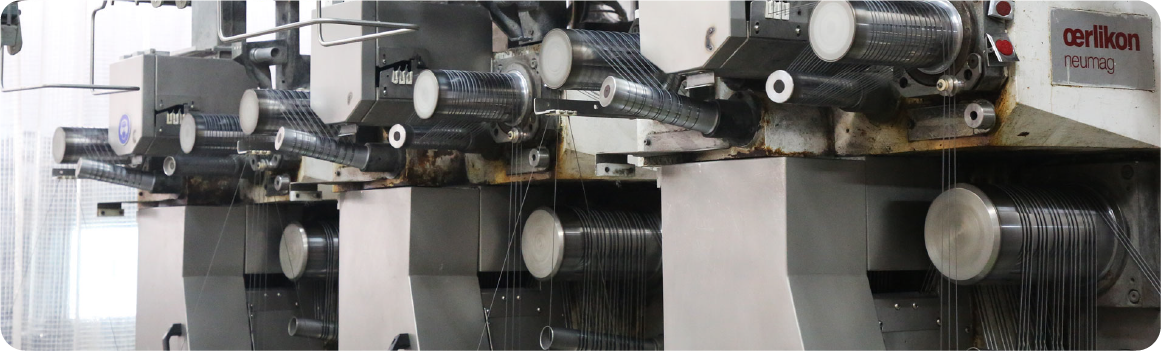

| spinned yarns | 1,000~3,000dtx polypropylene-BCF solution died yarns (single or tri-color) |

| processing | various kinds of processing after spinning is possible, such as ring twisting, cable twisting with or without heat-setting, intermingling or twist-mingling with other materials |

| colors | standard colors of about 100 |

| facility | vario melt spinning * 2 m/c with 9 positions made by Oerlicon Neumarg, Germany |

| matelial | 100% polypropylene |

| production | 400 tons/month |

| delivery time | standard delivery within 8 weeks for a lot of 7 tons |

|

TEL: +81-59-331-8351 | FAX: +81-59-332-1847 |